CNC Machining

Above All CNC offers CNC machining for industries that demand a high level of accuracy, consistent results, tight tolerances, and complex shapes. Whether it is high volume contracted production, or a low volume expedited prototype, we are your highest quality partner offering CNC machining services. To better meet the needs of our customers’ quality and regulatory requirements, we are ITAR registered, ISO 9001:2015 and AS9100D certified. Our team of expert programmers, machinists, quality personnel and technicians deliver a level of accuracy, consistency and precision second to none!

Manual Milling and Turning

Above All CNC’s machinists also provide unmatched expertise for a wide range of operations when manual control is ideal. Our manual machining services can cost less, provide quicker response, and reduce delays for our clients.

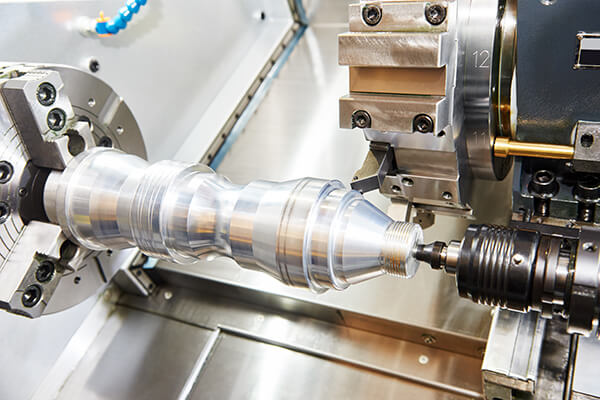

CNC Turning and Mill Turn

Above All CNC offers the highest standard in CNC lathe and Mill Turn services. This “One and done” approach can help you reduce process time utilizing some of the latest technologies.

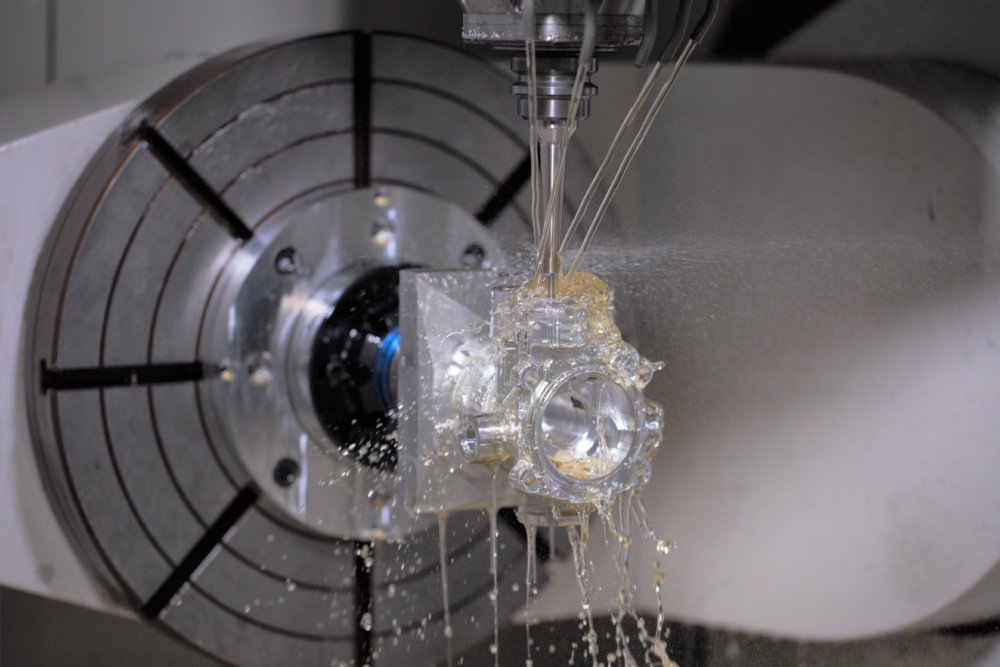

CNC Milling

Above All CNC offers 3, 4, and 5 axis CNC milling for our customers in the

aerospace, medical, defense, and commercial fields.

3-Axis Milling

Above All CNC’s 3-axis machining-center uses a cutting tool that moves along the X (Horizontal), Y (Vertical), and Z (Axial) axes to mill your part. Our 3-axis milling centers are best suited for machining 2D and 2.5D geometry such as basic contours, surfaces, and slots. They can also be used for drilling, tapping, reaming, and boring holes.

5-Axis Milling

Above All CNC’s 5-axis milling-centers significantly increase the range of possibilities by utilizing 3+2 machining as well as fully continuous 5 axis machining. 3+2 machining can produce highly complex parts by rotating the workpiece to any compound angle in relation to the cutting tool. Continuous 5 axis machining can produce not only planer and compound feature sets, but highly complex 3d shapes. This can give designers a huge level of flexibility when designing components destined for a CNC mill.

4-Axis Milling

Above All CNC’s 4-axis machining-center executes the same functions as our 3-axis machining centers but with an added 4th axis that allows for rotation about the X-axis. This added feature on our vertical mills allows for more complex shapes and sets of features which minimizes the number of individual set ups. The addition of a 4th axis allows us the ability to run high quantities of complex parts in a single cycle.

Horizontal Milling

Above All CNC’s high-speed horizontal milling machines can handle countless repetitions. By utilizing a 4th axis, pallet system and 120 tool magazine, the latest in horizontal milling technology enables us to produce more accurate parts in less time than the competition.

Call us and get it done

Above All CNC supplies the highest quality parts, services, and components for customers in a variety of industries To guarantee we meet the needs of our customers, we employ the highest skilled machinists, operators, and technicians in the field.

Why Choose Above All CNC?

Above All CNC strives to create partnerships designed to increase productivity and reduce overall costs for its customers. Our passionate team of professionals’ fresh insight on manufacturing helps us provide machining services at a competitive price that impacts your bottom line. Whether is prototype or production services you require the advantages of partnering with us include but are not limited to:

- Innovative and cost-effective solutions designed to increase productivity, ultimately saving you time and money.

- Streamlined processes designed to provide consistency and quicker lead times.

- In-house capabilities providing full-service machining.

- Top notch production personnel.

- Safe and green business practices designed to support workplace and environmental safety.

Frequently Asked Questions

CNC milling (Computer Numerical Control Machining) is a machining process which utilizes computerized controls and cutting tools to remove material from the workpiece, producing a specific product or part. This process is suitable for machining a wide range of materials such as metals, plastics, and composites, producing an almost unlimited variety of custom-designed parts and pieces.

CNC turning is as a machining process where bars of metal are rotated while a stationary tool is used to remove excess material until the desired shape is reached.

Mill Turn machining combines the functions of lathes and mills into one hybrid work center. The combination of sub spindles, multiple turrets, and milling tools enables these work centers to produce highly complex parts, often in a single operation.

3 axis machining involves a workpiece in a fixed position while the cutting tool operates along the X, Y, Z axis to cut away material. 3-axis machining is most suitable for parts that do not require compound angles or complex surfaces.

4-axis machining has the same functions as the 3-axis machining centers but with an added 4th axis that allows for rotation about the X-axis. This added feature on a vertical and horizontal mill allows for more complex shapes and sets of features which minimizes the number of individual set ups. The addition of a 4th axis allows us the ability to run high quantities of complex parts in a single cycle.

5-Axis machining centers significantly increase the range of possibilities by utilizing 3+2 machining as well as fully continuous 5 axis machining. 3+2 machining can produce highly complex parts by rotating the workpiece to any compound angle in relation to the cutting tool. Continuous 5 axis machining can produce not only planer and compound feature sets, but highly complex 3d shapes. This can give designers a huge level of flexibility when designing components destined for a CNC mill.

Prototype machining is a process in which smaller quantities of parts are produced. It could be that only a small amount of parts are required, or that a customer would like to prove out the production process before commitment to higher quantities. Prototype machining can provide an opportunity to validate form, fit and function.